Biocompatible Hydrogels for 3-Dimensional Printing with Light

3D-printing recently emerged as a very useful technology for producing complex shapes – from models of human organs to fully functional elements of cars. The printing is typically performed using layer-by-layer deposition of molten polymers. However, these conditions are incompatible with biological entities. Therefore, new biocompatible printing methods are sought for to produce tailor-made implants or for 3D cell cultures.

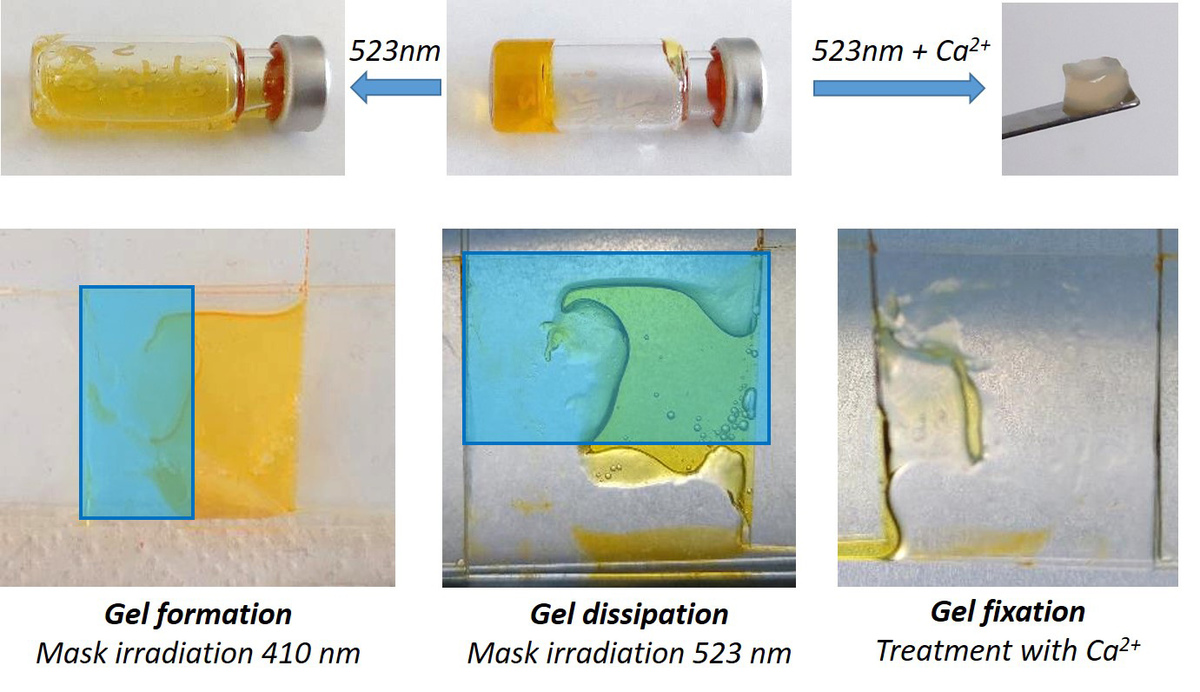

The group of Zbigniew Pianowski had developed supramolecular hydrogels containing molecular photoswitches, which are molecular “antennas” that enable conversion of the light energy into molecular motion. These hydrogels can be reversibly dissipated with visible light. They are biocompatible, and have been used as drug-delivery materials. The YIN Grant 2021 enabled us to perform preliminary investigation of the properties of our material in the 3D-bioprinting direction.

First, we have optimized the structure of molecular photoswitch, to enable dissipation with low-energy red light compatible with complex biological systems – these frequencies can deeply penetrate soft human tissues.3 Then, we developed a composite hydrogel, where the photochromic component is blended with an oppositely charged alginate (covalent non-photochromic sugar polymer). This formulation enables reduced loading of the photochromic agent. The resulting material can be reversibly photodissipated and forms defined shapes.

Once formed (e.g. with desired type of living cells inside), it can be treated with aqueous solutions of calcium salt – a strong cross-linker specific for alginate. This, together with general irradiation, liquefies the remaining photochromic component that is further washed away. The remaining shaped material contains only properly shaped fully biocompatible calcium alginate with the desired cells suspended in it.

Currently, with the support of a DFG grant5, we explore the use of our material for 3D-bioprinting of tailor-made implants for regenerative medicine. We also test our material as a smart support for growing organoids – functional 3D models for human tumors (tumoroids). It is known that mechanical properties of hydrogels are much more optimal for growing fragile cell and tissue cultures, in comparison to glass or plastic supports. And our goal is to dissipate the hydrogel with light after finished growth – so that the organoid can be isolated for further experiments in liquid media.