Utilizing 2D lattice defects to design novel reinforcements for nanocrystalline metals

Metals are still the primary material used in our society. They enable energy-effi cient turbines and the miniaturization of elec tronic devices. New technologies also push the boundaries for ma terial performance. As usual in life, all desired material properties cannot be optimized independently. The "strength-ductility dilemma", for example, hinders the application of ultra-strong ma terials, since the needed ductility is lost. For this YIN Grant, Karsten Woll and Christian Brandl combined experiments and simula tions to deduce reinforcement strategies for metals: While the experiments focus on structural signatures created through sol id-state transformation after annealing, the simulations allow to observe the underlying atomic mechanisms. Their results point to new materials design strategies where sim ulations reveal and validate process-struc ture-property relations and guide experi ments.

Nanoscale reinforcements of brittle materials can resolve the strength-ductility dilemma. The concept relies on a size effect, where brittle materials become insensitive to initial flaws below a critical size. The key for this strategy is the reliable processing which results only in nano meter enforcements. Based on the control of the nucleation and growth of the hard compounds in a solid binary alloy, the material can be tuned by temperature protocol during annealing.

Multilayers are prototype materials to explore the potential of nanoscale precipitation in periodic stacking of dissimilar metals. The interfaces of the different metals as well as grain boundaries within the layers confine dislocation movement causing extraordinary strength. The detailed structure of grain boundaries also influ ences how precipitation of inter-metallic phases occurs in multilayers. It is not clear, however, what protocol to use to limit the precipitation to the nanometer scale to get a flaw insensitive and strong composite.

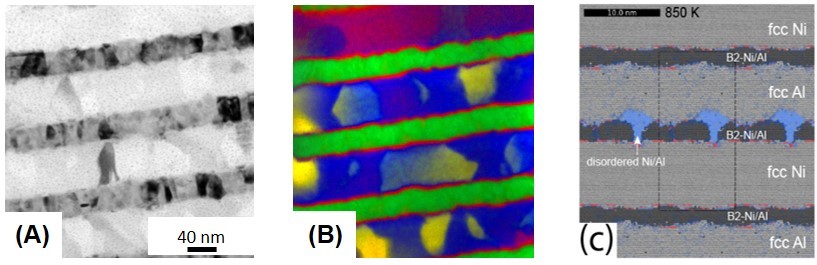

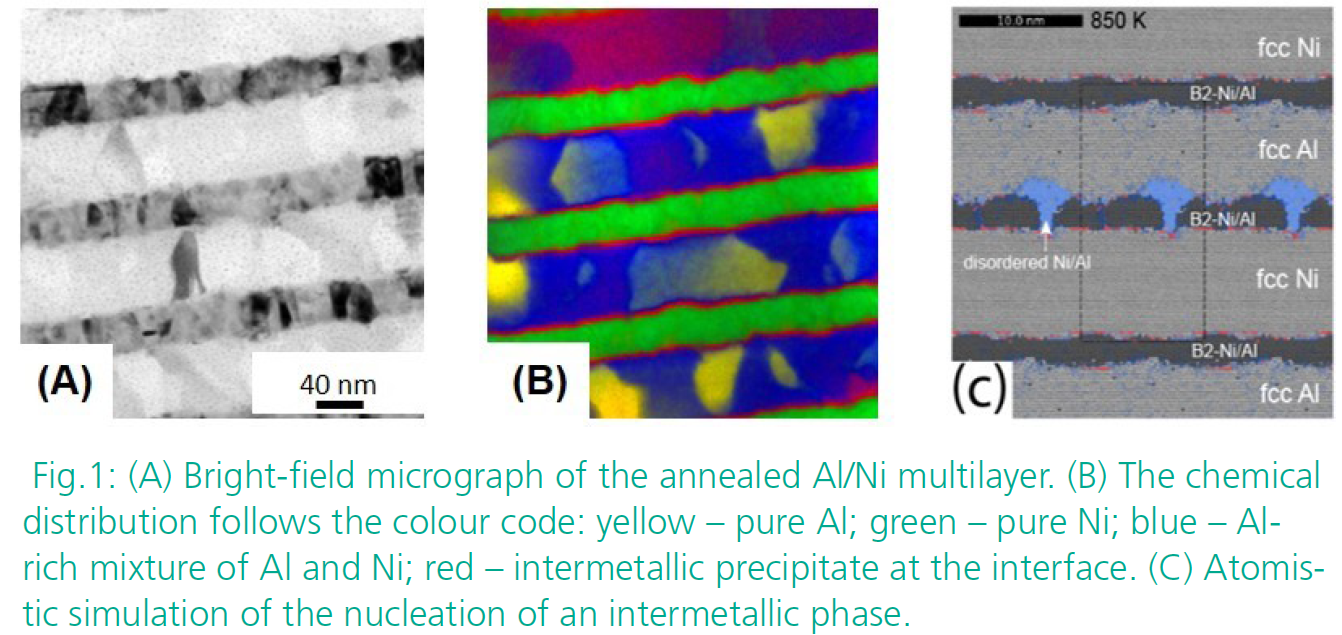

In initial experiments*, the chemical distri bution of annealed multilayers (Fig. 1A-B) demonstrate that Nickel (Ni) intermixes with Aluminum (Al) and a product phase nucleates at the Al/Ni interfaces. Comple mentary molecular dynamics simulations allow to directly observe the atomic mass transport during the annealing at elevated tem peratures. The processes of precipitate nucleation and growth are again related to the asymmetric diffusion of Ni into Al along existing and newly formed interfaces (Fig. 1C).

An interfacial layer may shield the Ni layer. The growth of the inter-metallic NiAl layer, then, re quires atoms diffusing from the Ni layer through the inter-metallic precipitate along grain bound aries to the Al layer. It is known from previous simulations that diffusion depends on the atomic structure of the grain boundary. Thus, controlling its population allows to control the diffusion and dictates the required temperature-time profile to determine shape and thickness of the precip itate. This work shows that solid-state interfaces guide the emergence of reinforcing inter-metallic phases. Their shape and size is controlled by dif fusion at or along interfaces in Ni/Al multilayers.