Deformation in high-strength composites

Processable like metal and at the same time strong as glass? Composite materials combine different properties but also imply challenges such as the metallurgic and mechanical interaction of the constituents. To better predict damage or crack evolution in aluminum reinforced with metal glass, composite scientist and YIN-alumnus Prof. Kay Weidenmann joined hands with Dr.-Ing. Katrin Schulz working on dislocation-based continuum models. The idea took form during an open-air lunch break in summer 2014 – one year later the results could be presented at the 20th International Conference on Composite Materials Copenhagen.

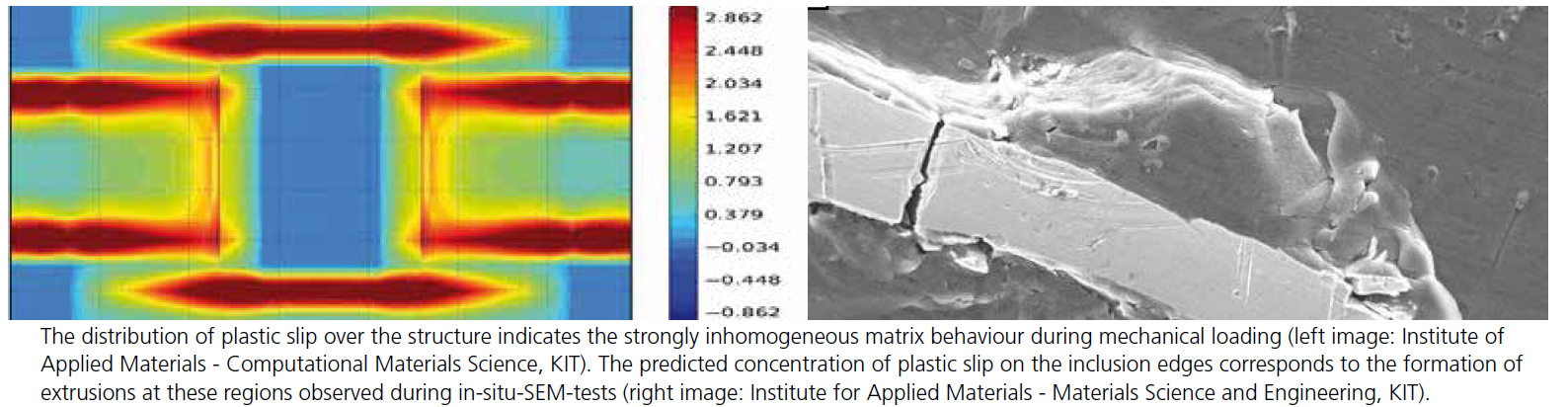

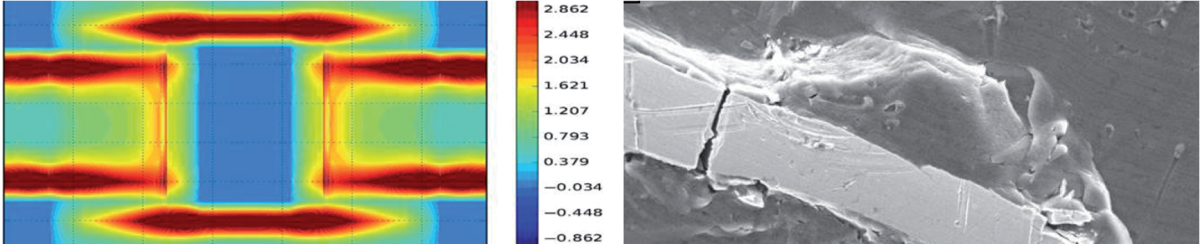

This YIN grant investigated the evolution of plastic deformation and micro cracks in metal matrix composites reinforced with metallic glasses made from Ni60Nb20Ta20. The deformation behaviour was investigated experimentally by means of in-situ characterization of the composites under compression. The results from the materials characterization are compared to numerical analyses. A dislocation-based continuum model is adapted to the microstructure and allows to investigate the interaction between the impenetrable particles and the surrounding aluminum matrix. Local stress concentrations are analyzed which occur in these composites due to inhomogeneous dislocation movement and, hence, cause plastic deformation in the composite material. The predicted regions of high plastic slip concentrations in the model composite coincided with the occurrence of extrusions of matrix material during insitu compression, hence proving the quality of the modelling approach used.

We did not expect to find such a good coincidence of the simulated forecast of the plasticity and the experimental results. This encouraged us to present this outcome on the 20th International Conference on Composite Materials in Copenhagen in July 2015, the largest conference on composite materials worldwide.