Oleogels from pectin particles for fat reduction in fine bakery goods – OLEOBAKE

In high-income countries, obesity and overweight are key risk factors for heart diseases, stroke, and type 2 diabetes. One possibility to lower the calorie intake is the reformulation of existing food products. This is particularly interesting in high-fat products, such as fine bakery goods. Here, it is mostly the high amount of butter that poses the highest risk factor. However, butter also provides the typical taste and texture. Hence, the challenge is not only to replace butter, but also to find alternatives that preserve its typical baking qualities. With their YIN grant OLEOBAKE, Ulrike van der Schaaf and Katharina Scherf investigate how liquid plant oils structured by pectin-based microgel particles perform in fine bakery goods.

Butter, but also hardened plant oils and fats, mainly consist of saturated fatty acids that are a specific high-risk factor for heart diseases. Yet, they also possess several unique technological features that lend baked goods their desired product properties: they are solid at room temperature, melt at body temperature, are spreadable, and give structure and texture to doughs and baked products. Liquid plant oils are a healthier alternative: built from unsaturated fatty acids, they have been identified to reduce inflammatory and ischaemic heart diseases. In order to provide liquid oils with some essential technological features of fats, they need to be immobilized. Typical gelators are waxes, e.g. from

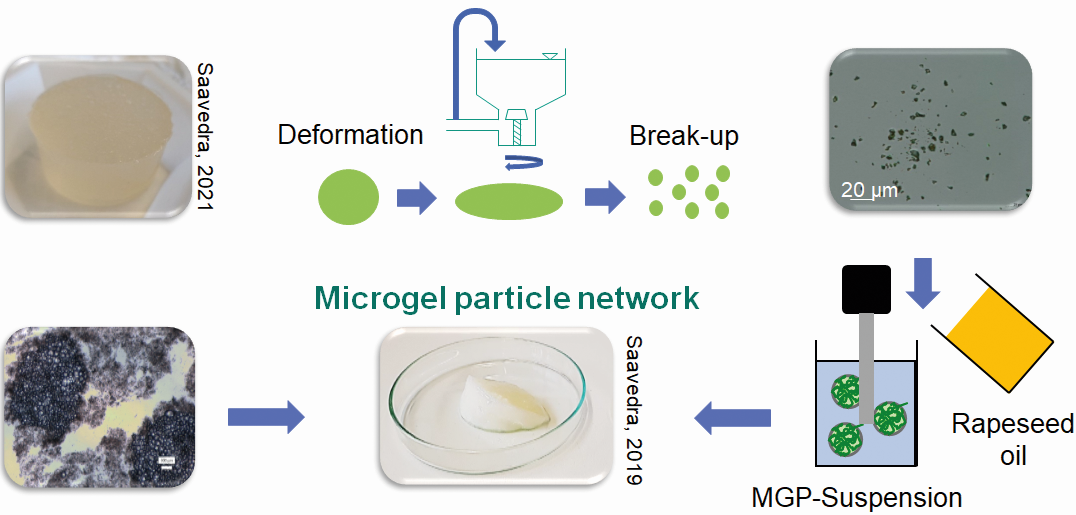

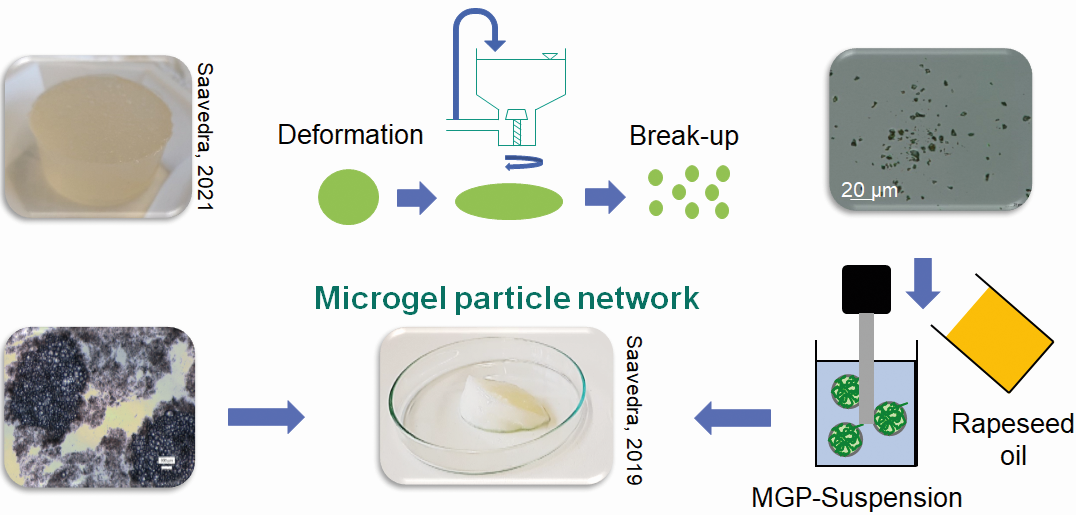

bees or rice bran, or ethylcellulose. Ulrike van der Schaaf and colleagues recently showed that pectin microgel particles can also be used to gel a liquid oil phase (Saavedra/Schaaf, 2020). Pectins are polysaccharides found in the cell wall of higher er plants. Obtained from side and waste streams of the food industry, they make a sustainable and cheap alternative. "We will prepare microgel particle suspensions using amidated and sugar beet pectin to modulate particle hardness and two different homogenization processes to vary particle size," says Katharina Scherf. The microgel suspensions will further be used to prepare oleogels by high shear mixing with 10%, 20%, 30%, and 40% rapeseed oil. All oleogels will be characterized for the following features: microstructure, flow properties, lubricating properties, and spreadability. In a second step, they will take the place of butter at 10%, 25%, 50%, and 100% in standard recipes for cake, cookies, and brioche. Testing this approach on sand cake has already led to first results: with increasing substitution of butter, baking loss and density increased as well as elasticity and cohesion. A trained sensory panel

rated products with the gel containing 30% rapeseed oil most similar to the control sample baked according to the original recipe. Odor, mouthfeel, and taste were comparable, only the appearance of the crumb was less appealing. The latter varies with baking time and temperature and can be adapted. That makes pectin-based oleogels suitable as a butter substitute in sand cake and the project is to continue. The first results were published in Food Chemistry Supplement Volume 3, doi: 10.1002/lemi.202359147