Modelling microstructural volume variations and the resulting mechanical properties in Li-ion batteries

Rechargeable lithium-ion batteries have revolutionized individual electrified transportation. New materials promise to further decrease the weight and volume of batteries by enabling greater energy densities. With regard to faster recharge, this concerns especially the negative electrode. Alternative materials to the state of the art graphite, however, suffer extensive volume variations upon charge and discharge, which need to be buffered by the overall electrode design. To tackle this issue, Dominic Bresser and Katrin Schulz initiated the joint development of a suitable electrode model: by gaining an in-depth understanding of the critical parameters defining volume changes, electrode architectures can eventually be tailored to minimize this effect.

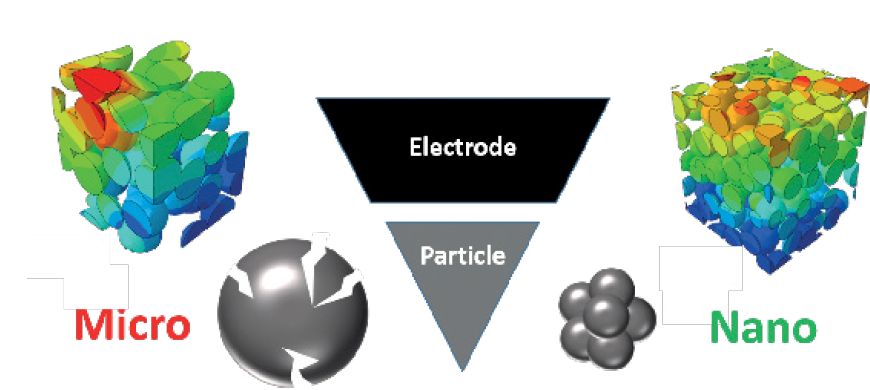

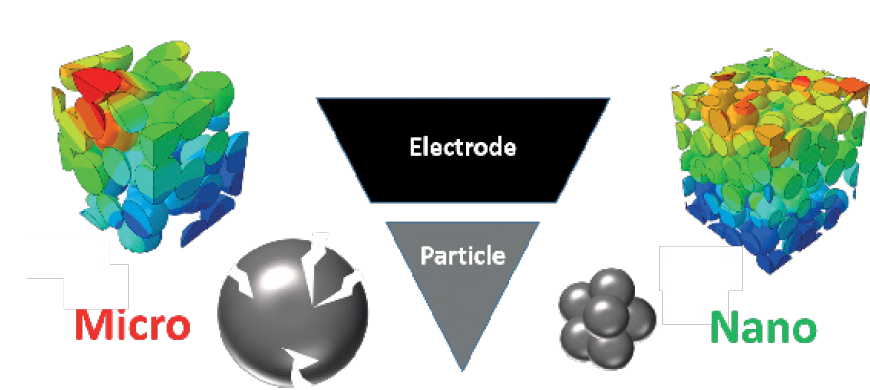

So far, clear guidelines how to address the changes in volume are missing – especially for commercially viable solutions. When considering the essentially needed and potentially added electrode components and important parameters such as the electrode porosity as well as the active material particle size and morphology, this task can become arbitrarily complex. We need to understand how volume changes at the particle level translate into volume changes at the electrode level.

Dominic Bresser is head of one of the worldwide leading experimental groups in the field of conversion/alloying materials that provide greater lithium storage capacities and faster charge rates compared to graphite as the state of the art.

Katrin Schulz and her group focus on reliable numerical methods for materials simulation. Based on high performance computing, they aim at multiscale approaches to represent different materials’ length scales in their models. Thus, physically based bottom-up formulations can yield new insights into material processes on micro and nano scale that are not or only with high effort accessible by experimental methods.

As a first outcome of their YIN grant collaboration in 2020, Dominic Bresser and Katrin Schulz together with their groups have developed an electrode model consisting of two phases: It simulates the evolution of the electrode as a function of the varying particle size upon discharge and charge. The results are in good agreement with the experimental findings and will be reported in a joint paper that has been submitted for publication. Further investigations will focus on the material behavior upon extensive cycling of the electrode, the introduction of additional phases, and the potential evolution of cracks in the electrode as well as in the single particles. The final goal is to develop a model that allows for predicting ideal electrode architectures for high-energy anode

materials that enable negligible volume variation at the electrode level and, thus, long-term stable cycling of the resulting battery cells.